Understanding Structural Steel Fabrication

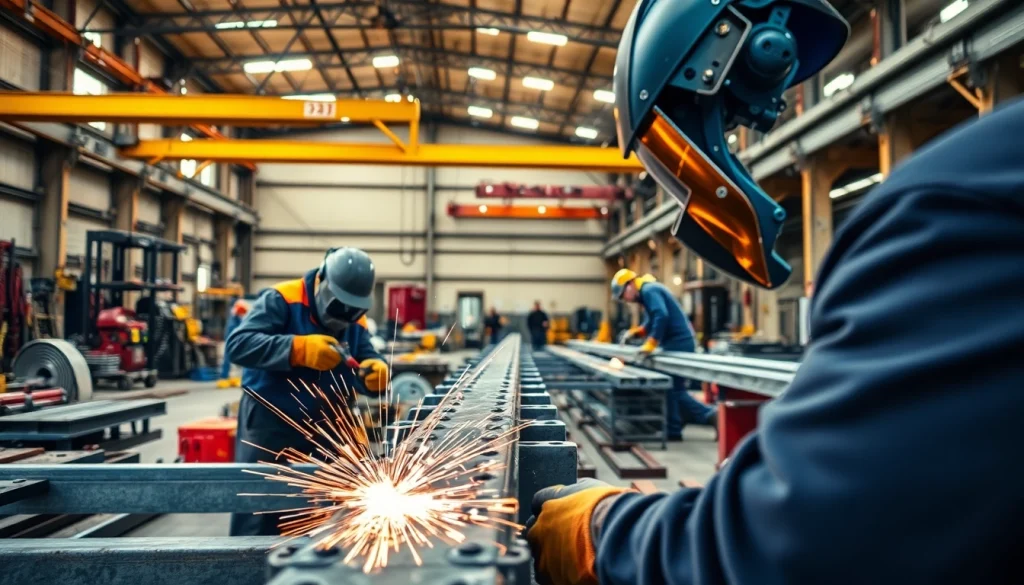

Structural steel fabrication is a foundational aspect of modern construction, playing a vital role in the integrity and longevity of buildings and infrastructure. It refers to the process of cutting, shaping, and assembling steel components to create a framework that can support various structures. Understanding this process is crucial not only for architects and engineers but also for anyone involved in construction, design, and project management. By grasping the nuances of structural steel fabrication, stakeholders can improve project outcomes and ensure compliance with safety and quality standards.

What is Structural Steel Fabrication?

At its core, structural steel fabrication involves taking raw steel, usually in the form of beams, plates, and shapes, and transforming it into components that can be erected on-site for various construction projects. This complex process includes several stages, such as detailing, cutting, welding, and assembly. It is conducted in controlled environments, like fabrication shops, to ensure precision and adherence to specifications.

Importance in Modern Construction

Structural steel is appreciated for its superior strength-to-weight ratio, durability, and versatility. These characteristics make it the preferred material for a wide variety of applications—from high-rise buildings to bridges and factories. Furthermore, as urban environments grow denser and construction budgets tighten, the efficiency of structural steel fabrication becomes even more critical. Structures built using steel can often be completed faster than those made from traditional materials, thereby reducing labor costs and timeframes.

Common Materials Used

While steel itself is the primary material in structural fabrication, various other materials enhance performance, aesthetics, and safety. Common materials include:

- Steel Alloys: Different alloys, like carbon and stainless steel, offer varying levels of strength, corrosion resistance, and weldability.

- Paints and Coatings: These provide protection against rust and other corrosive elements.

- Insulation Materials: Often used in conjunction with steel structures to enhance energy efficiency.

Key Processes in Structural Steel Fabrication

Cutting Techniques for Precision

Precision cutting is critical in structural steel fabrication, as accurate dimensions ensure that components fit together correctly during assembly. Common cutting techniques include:

- Oxy-Fuel Cutting: This method uses a flame fueled by oxygen and acetylene to cut through steel. It is ideal for thicker materials.

- Plasma Cutting: This technique ionizes gas, creating a high-temperature arc that can slice through metal. It is particularly effective for intricate shapes.

- Laser Cutting: Known for its precision, laser cutting utilizes a focused beam of light to achieve meticulous cuts in steel.

Welding Methods and Their Applications

Welding is the process of joining two or more pieces of metal together using heat, pressure, or both. Different welding methods are employed depending on the project requirements:

- MIG Welding: Metal Inert Gas (MIG) welding is popular for its speed and versatility in joining thin to medium gauge metals.

- TIG Welding: Tungsten Inert Gas (TIG) welding provides high-quality welds suitable for thinner materials.

- Arc Welding: This method involves electric arcs to melt metal and create strong joints, often used for heavy-duty applications.

Finishing Processes and Quality Control

Post-fabrication processes are vital in ensuring the performance and aesthetic quality of the finished product. These include:

- Sandblasting: This process removes rust and other contaminants from the steel surface, preparing it for finishing.

- Painting and Coating: Protective coatings prolong the life of structural steel by preventing corrosion.

- Quality Assurance Tests: Rigorous testing, such as ultrasonic and magnetic particle testing, ensures the integrity of the welds and overall structure.

Best Practices for Structural Steel Fabrication

Planning and Design Considerations

A well-thought-out design and planning phase is crucial in the fabrication process. Key considerations include:

- Load Calculations: Structural engineers must perform load calculations to determine the appropriate steel size and shape.

- Building Codes: Familiarity with local, state, and federal building codes ensures compliance and safety standards are met.

- Collaboration: Close collaboration between architects, engineers, and fabricators can prevent costly design changes and delays.

Safety Measures in the Fabrication Process

Safety should always be a priority in structural steel fabrication. To mitigate risks, implement the following measures:

- Personal Protective Equipment (PPE): Workers should wear appropriate PPE, including helmets, gloves, goggles, and steel-toed boots.

- Training Programs: Regular safety training for all employees is essential to prevent accidents and ensure everyone understands safety protocols.

- Workplace Organization: Maintain an organized workspace to reduce hazards and optimize workflow efficiency.

Maintaining Quality Standards

Quality assurance is vital to the success of any fabrication project. To maintain high standards, companies should focus on:

- Inspection and Testing: Regular inspections and testing should be conducted throughout the fabrication process to catch any defects early.

- Standard Operating Procedures: Develop and train employees on SOPs for every stage of fabrication to ensure consistency and quality.

- Continuous Improvement: Implement a culture of continuous improvement to identify inefficiencies and enhance production methods.

Challenges in Structural Steel Fabrication

Identifying and Overcoming Common Issues

Despite the advancements in technology and processes, structural steel fabrication faces several challenges. Common issues include:

- Material Defects: Unexpected defects in raw materials can arise, requiring a robust quality assurance system to detect and address them early.

- Equipment Malfunctions: Regular maintenance and upgrades to equipment are essential to prevent downtime and production delays.

- Labor Shortages: Skilled labor shortages can impact project timelines; therefore, investing in training and retention programs for craftsmen is vital.

Impact of Regulations and Standards

The steel fabrication industry is heavily regulated. Compliance with regulatory standards such as OSHA and ASTM can impose strict guidelines that affect every aspect of the fabrication process. Adherence includes:

- Documentation: Maintaining detailed records of inspections, tests, and certifications aids in compliance and accountability.

- Regular Audits: Conducting periodic reviews and audits ensures ongoing compliance with safety and quality regulations.

Dealing with Supply Chain Fluctuations

Supply chain disruptions can significantly affect the availability and cost of materials necessary for fabrication. To mitigate such impacts, businesses can:

- Establish Diverse Suppliers: Working with multiple suppliers can reduce the risk of being overly reliant on a single source.

- Inventory Management: Regularly assess inventory levels and adopt just-in-time inventory practices to maintain workflow continuity.

Future Trends in Structural Steel Fabrication

Technological Advancements to Watch

As technology continues to evolve, the structural steel fabrication industry must adapt and innovate. Key advancements include:

- 3D Printing: The adoption of 3D printing technology is increasing, enabling the creation of complex steel components with reduced waste.

- Robotics and Automation: Robotic systems are being integrated into factories to enhance production speed and precision while minimizing human error.

- Building Information Modeling (BIM): BIM tools allow for advanced modeling and simulation, streamlining collaboration between design, fabrication, and construction stages.

Sustainable Practices in the Industry

Environmental concerns are prompting the industry to adopt more sustainable practices. These include:

- Recycling Steel: Utilizing recycled steel helps reduce carbon footprints and prioritizes eco-friendly practices.

- Energy Efficiency: Implementing energy-efficient processes in fabrication shops lowers costs and environmental impact.

- Green Certifications: Achieving certifications such as LEED can help companies demonstrate their commitment to sustainability.

Innovation in Design and Engineering

Future structural steel designs are likely to become more innovative as engineers explore new methodologies. Emerging trends include:

- Smart Materials: The use of smart materials that respond dynamically to environmental conditions can enhance structural integrity and performance.

- Modular Construction: Prefabricated modular steel components allow for quicker assembly on site, minimizing labor and time costs.